Product Application

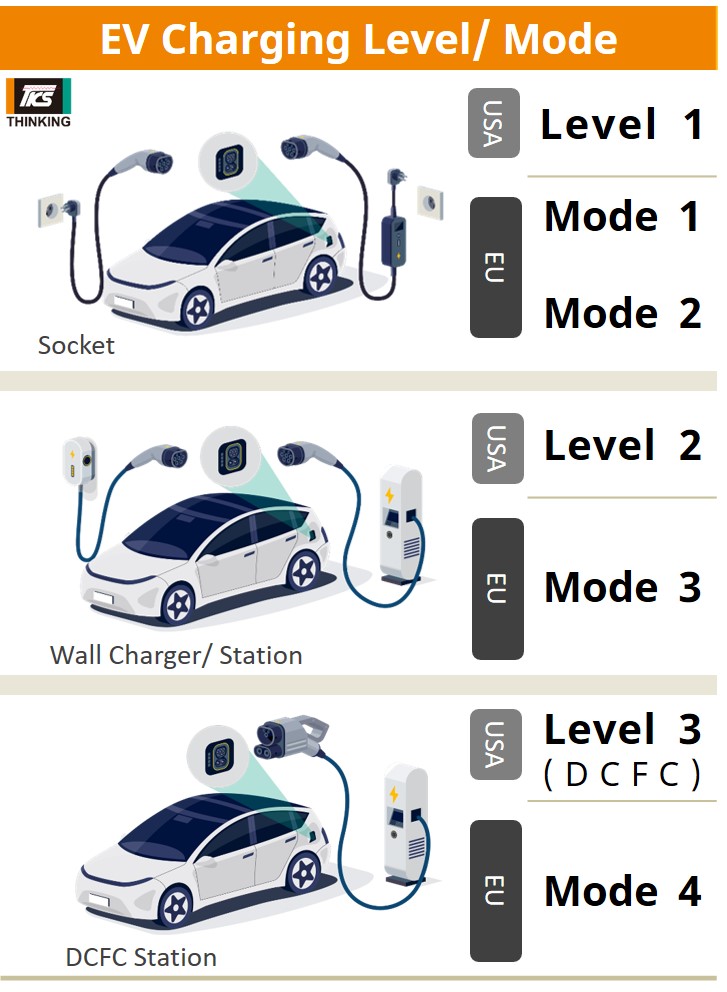

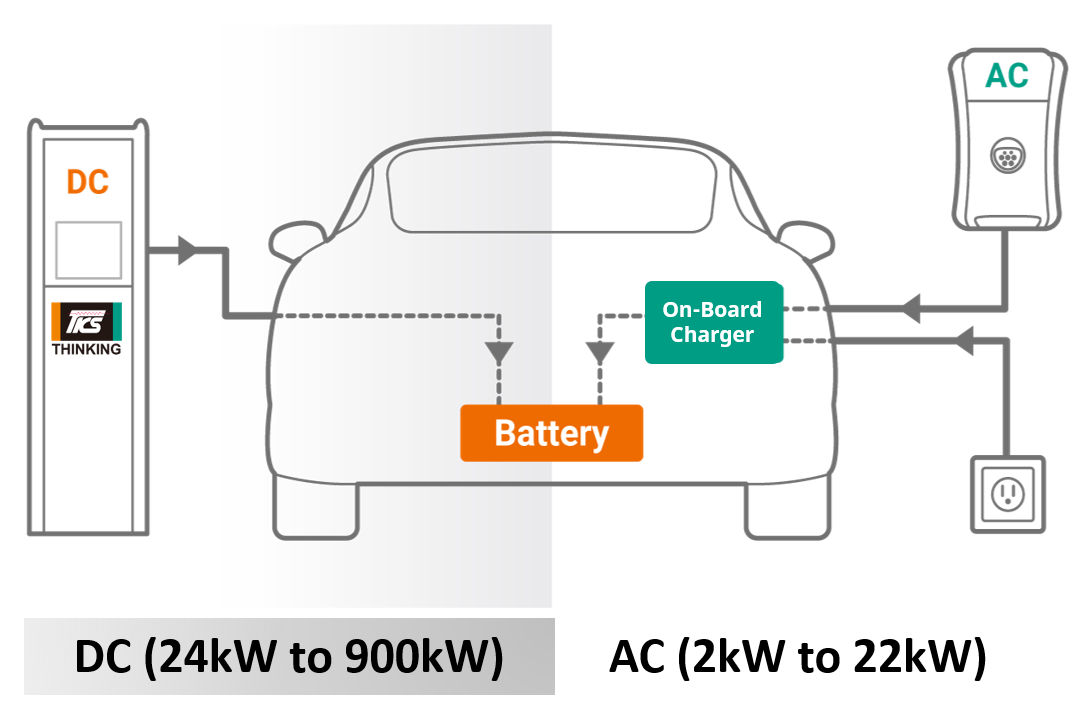

The charging system of the battery pack is an indispensable subsystem for both pure electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs). It converts electrical energy from the grid to power the electric vehicle's battery pack. The charging system consists primarily of two major components: the electric vehicle supply equipment, so-called off-board charger or charging station, and the on-board charger. Based on the output currents the charging station supplies, there are two types of electric vehicle power supply equipment: DC and AC charging.

The AC charging station transmits AC power from the power grid through a charging cable to the on-board charger of the electric vehicle. Next, the on-board charger converts the AC power into DC power and supplies it to the battery system. However, with its limited size and weight, the on-board charger in an electric car can only provide a charging power of 22kW or less, making the charging speed of AC charging slower.

On the other hand, a DC charging station converts AC power from the grid into high-voltage DC with its built-in AC-to-DC converter. With AC-to-DC power conversion at the DC charging station, the electric vehicle can receive tens to hundreds of kilowatts of power, reducing charging time. However, a DC fast charging station contains more power semiconductors for power conversion modules and is, therefore, technologically complex and more expensive than an AC charging station.

During charging, electrical threats such as power surges, inrush current, and overheating can damage the EV supply equipment, the user, and the vehicle, regardless of whether it is AC charging or DC fast charging. Accordingly, electric vehicle supply equipment must include reliable over-voltage, overcurrent, and over-temperature protection schemes. THINKING provides circuit protection solutions that electric vehicle supply equipment needs to ensure safe operation and promote long-term reliability.

Over-Voltage Protection

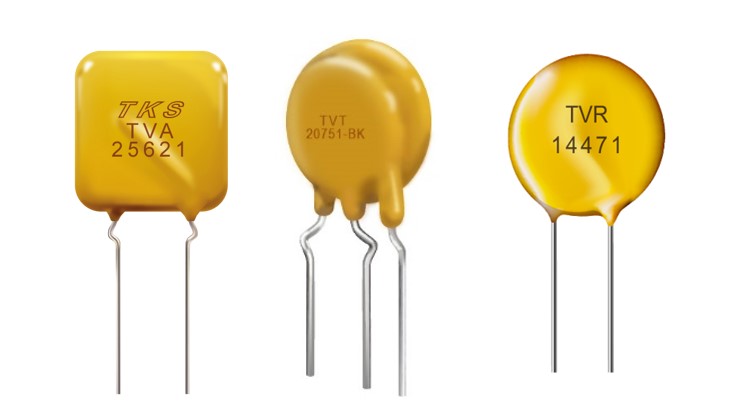

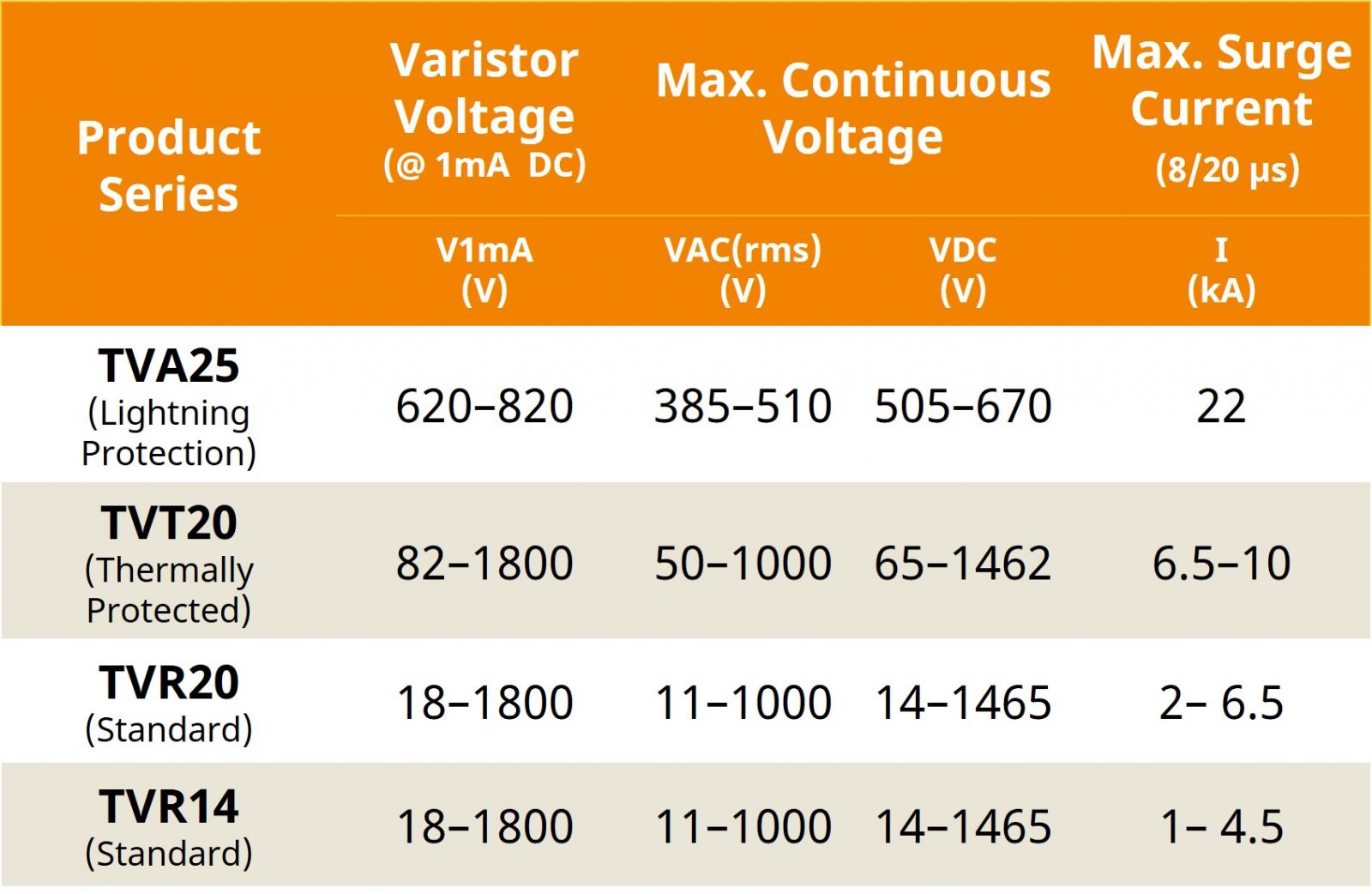

Since most AC and DC charging stations are fed AC power from the electrical grid, power surges may transmit to the charging station via the AC power input line. Furthermore, the charging stations may locate outdoors with the threats of lightning strikes or near a facility with a heavy industrial motor that may induce voltage surges. Therefore, the charging station needs a surge protection solution that can withstand high-voltage transients. THINKING provides two lightning protection solutions. For DC fast charging stations situated outdoors, it is recommended to include THINKING high-energy metal oxide varistor, TVA25 (25mm) series for lightning surge protection. For DC or AC charger placed indoors, the combination of the radial leaded type varistor of TVR series or TVT series (Ф14mm or Ф20mm) with gas discharge tubes is the ideal transient suppression solution for primary circuit.

Metal oxide varistor

● The TVA series is the metal oxide varistor designed to absorb high-surge energy produced by a lightning strike. The series is available in various forms and sizes and offers high surge current withstanding capability.

● The TVT series is the thermally protected metal oxide varistor from THINKING. It is comprised of MOV with a thermal fuse element designed to open when overheating occurs under frequent over-voltage conditions. There are two-terminal and three-terminal versions of the device. The inclusion of a third monitor lead helps indicate whether the MOV has been disconnected from the power circuit or not, making the device fail-safe.

● The TVR series provides a wide range of operating voltage, and is with high surge protection capability.

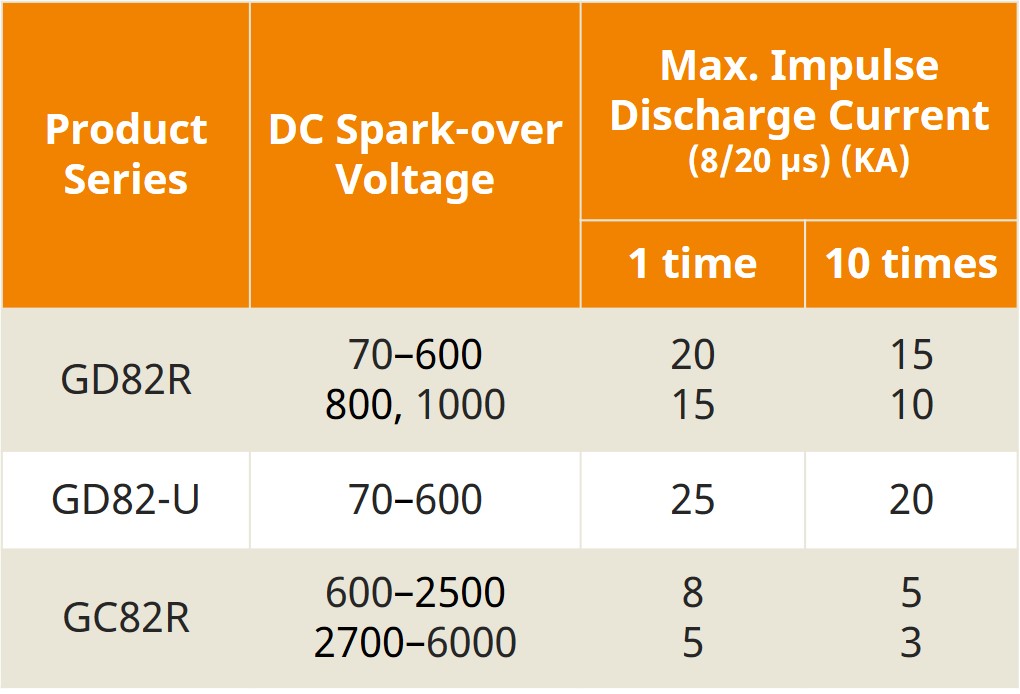

Gas discharge tube

Its high insulation resistance, very low capacitance, and high surge current handling capabilities make gas discharge tube (GDT) an optimal choice for protecting AC lines against lightning and other power surges. THINKING GDTs are available in various surface mount and leaded configurations and in a wide range of DC spark-over voltages to meet the needs of a broad range of applications. Among them, the two-electrode type GDT is often used for line-to-ground or line-to-line protection.

Over-Current Protection

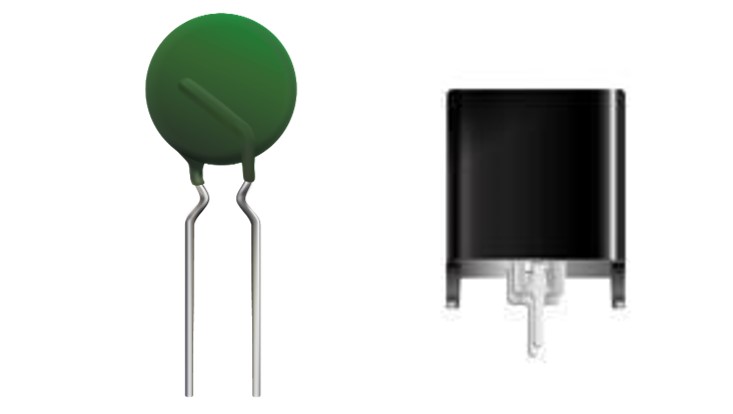

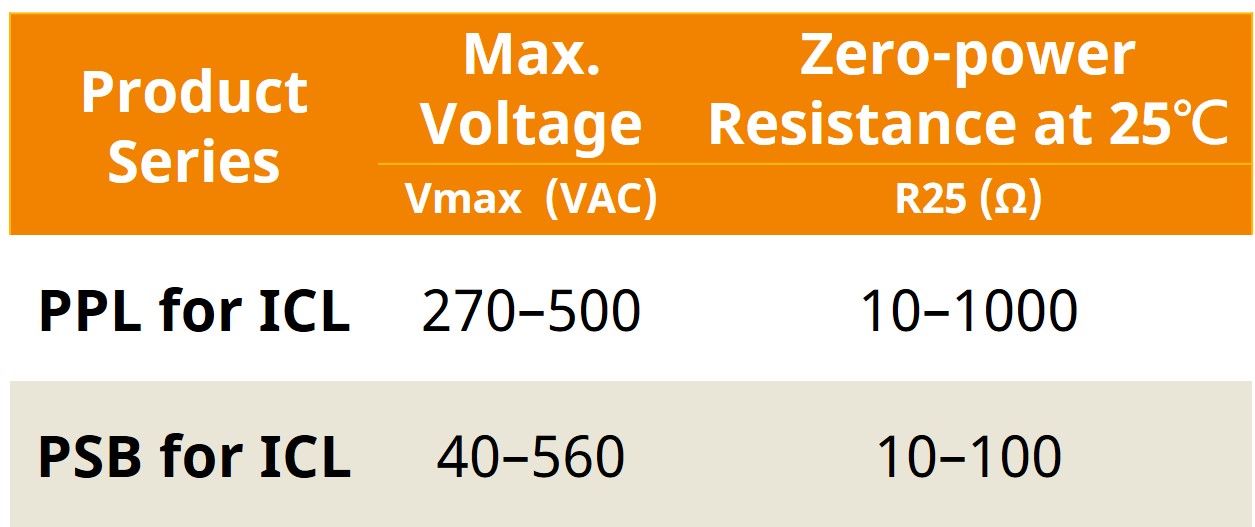

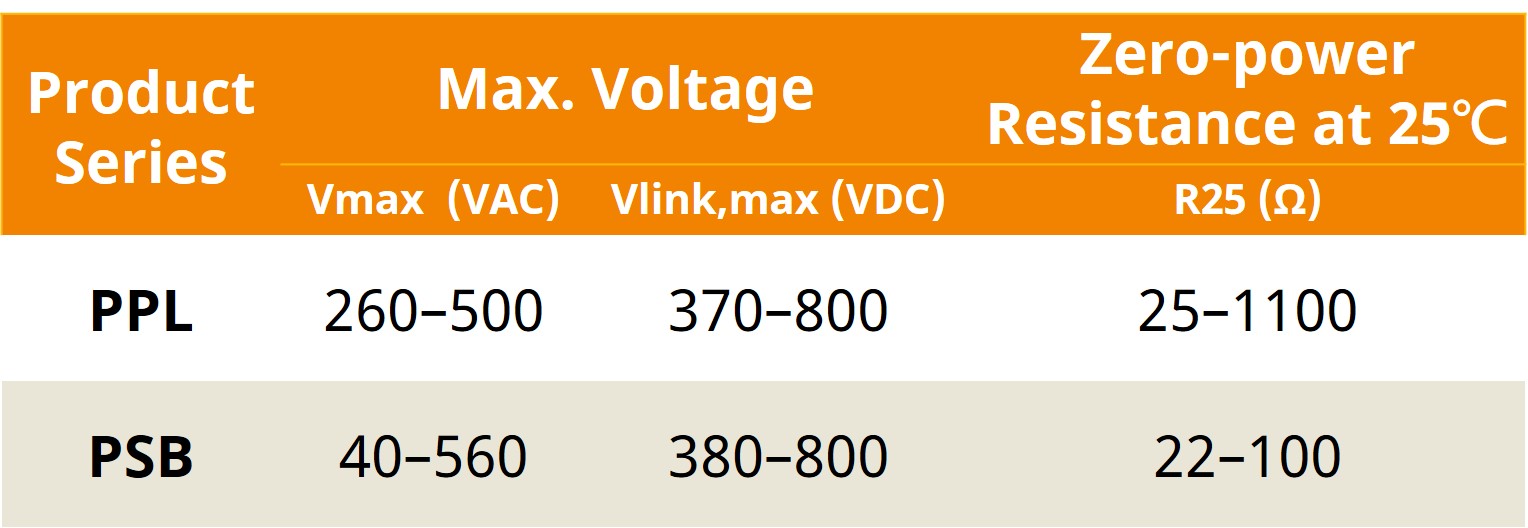

Cermaic PTC Thermistor for Inrush Current Limiting

When the charging station is powered-up, a high peak inrush current flows into the equipment, which can harm the semiconductors or other components. THINKING recommends using a ceramic PTC thermistor as an inrush current limiter to limit this abnormal current. A ceramic PTC thermistor is a thermally sensitive semiconductor mainly made of ceramic. The ceramic PTC thermistor has relatively low resistance values at room temperature. However, as current passes through the thermistor and generates heat, its resistance significantly increases at a specified temperature point. This unique property makes PTC thermistor an ideal solution for over-current protection. The PPL and PSB series of THINKING ceramic PTC thermistors can limit inrush currents and provide robust protection for the power supply circuit.

Cermaic PTC Thermistor for discharging capacitor

Besides serving as an inrush current limiter, ceramic PTC thermistors can also be used to discharge high-voltage capacitors in DC charging stations. Because the high-voltage energy stored in capacitors can cause electrical shock even when the power supply has been disconnected, designers should integrate appropriate discharge mechanisms into the circuit. Incorporating the ceramic PTC thermistor to discharge capacitors is a safe, effective, and reliable choice. Ceramic PTC thermistor can withstand high voltages and absorb excessive energy because of its material properties. Compared with using a fixed resistor as a discharging resistor, ceramic PTC thermistor has a higher voltage-withstanding capability and require fewer components than fixed resistors, which can significantly save board space and reduce overall costs. Customers can choose from different resistance values and voltage ratings for ceramic PTC thermistors offered by THINKING.

Over-Temperature Protection

Since DC charging stations require AC-DC conversion, more power semiconductor devices, such as MOSFETs and IGBTs, are utilized in the power conversion modules. Power semiconductors generate heat when operating and require temperature monitoring to prevent high transistor junction temperatures. Using NTC temperature sensors to monitor the temperature of semiconductor devices can help ensure these sensitive and valuable semiconductor components stay at their optimal operating temperatures.

There are various configurations of THINKING NTC temperature sensors to meet different design requirements. The NTSE series is an epoxy-coating type temperature sensor with a small sensing top, a simple structure, and high commonality. The NTSA series ring terminal temperature sensors are available in a wide range of terminal sizes (M2.5 to M10) and can be fastened with simple screw-on installation. Finally, the surface-mount type temperature sensor, TSM series, is small, lightweight, fast in response, and suitable for automated production to improve customers' production efficiency.

Public AC or DC charging stations installed in commercial spaces such as malls, office buildings, and highway service areas usually have communication interfaces and human-machine interfaces such as touchscreen, which can be threatened by ESD (Electrostatic Discharge) transients. When users interact with the touchscreen, the ESD transients are introduced into the charging equipment via the touchscreen and can potentially damage the ICs. Therefore, comprising the interface circuits with a robust ESD suppression solution is critical. The LCP series and ESD TVS are ideal ESD protection devices with low capacitance and fast response. Their ability to suppress rapid-rising ESD voltage transients without introducing additional capacitance helps keep signal integrity intact.

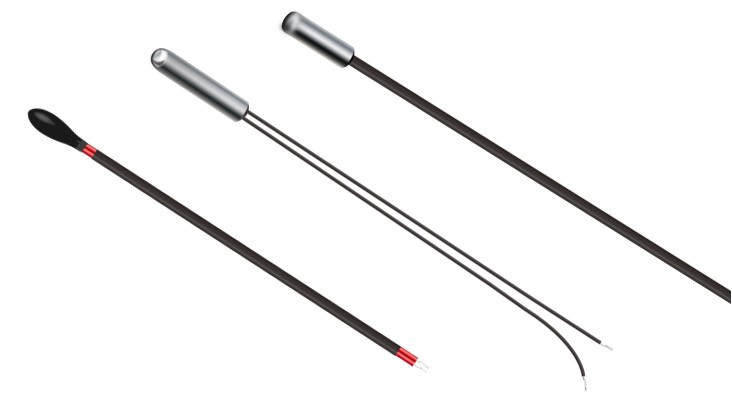

Electric vehicles need a charging cable for connection, whether slow AC or DC fast charging. A charging cable's power contact, particularly that of a DC high-power charging cable, transmits a high current that may generate significant amounts of heat during charging and endanger the user's safety. Therefore, integrating a temperature sensor at each DC contact to monitor its operating temperature is essential for ensuring the safety of high-speed charging. Once the power contact temperature exceeds a designated value, the charge controller of the charging station will stop the charging process or reduce the charging power to protect the user, the vehicle, and the charging equipment.

THINKING provides a variety of accurate NTC and platinum temperature sensors that are suitable for integrating with the power contacts to meet the design requirements of various types of AC slow charging and DC fast charging cables. In addition, for DC charging guns of high-voltage applications, THINKING can provide temperature sensors with high dielectric strength (>3500VAC) to ensure the stability and reliability of the charging process.

NTC temperature sensors include the epoxy-coating NTSE series and the screw-on NTSA series. Platinum (Pt) temperature sensor has positive temperature coefficient characteristics and excellent accuracy and stability in harsh environments. THINKING’s platinum temperature sensors for EV charging cables are available in different packaging. The Pt1000 chip can be enclosed in a metal housing, plastic case, or dual-layered heat-shrink sleeve to meet various requirements.